Materials used to make the hoses need to strike a balance between different requirements

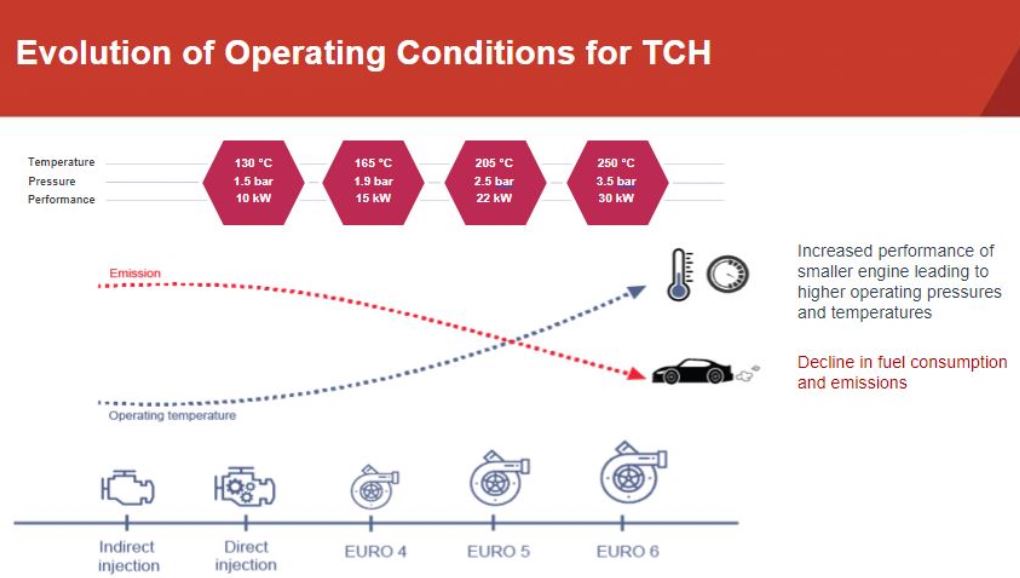

Changes in automobile design, the rise of technologies to increase fuel economy and reduce emission as well as extended warranties, have affected the conditions to which turbocharger hoses are exposed. Consideration of these conditions can help determine the appropriate material to use for turbocharger hose applications.

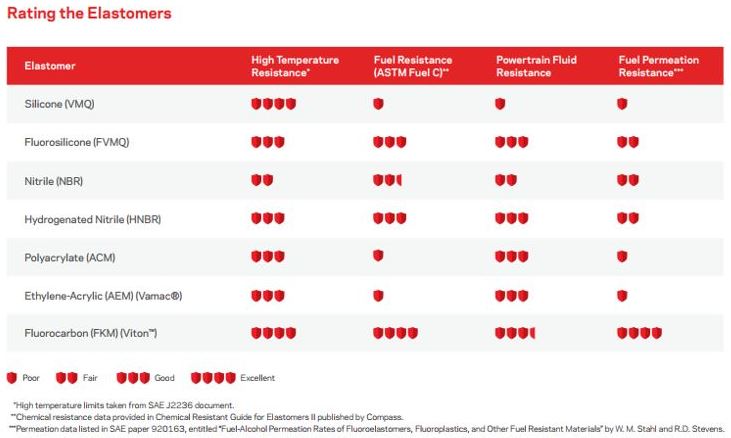

Selecting the right material to add during the manufacturing process requires a good evaluation of the material’s properties, including temperature, chemical, and fuel permeation resistance, as well as durability.

Turbocharger hoses get exposed to increasing stress as engines become smaller and operate at higher temperatures. Viton™ fluoroelastomers are engineered and formulated to operate in those harsher conditions, enabling you to demonstrate improved performance to your customers for years to come and minimize the need for re-design as demands increase.

Here’s how Viton™ fluoroelastomers compare to the next-best alternatives in turbocharger hose applications:

Download your Guide Now

Download your Guide Now